|

|

|

|

|

|

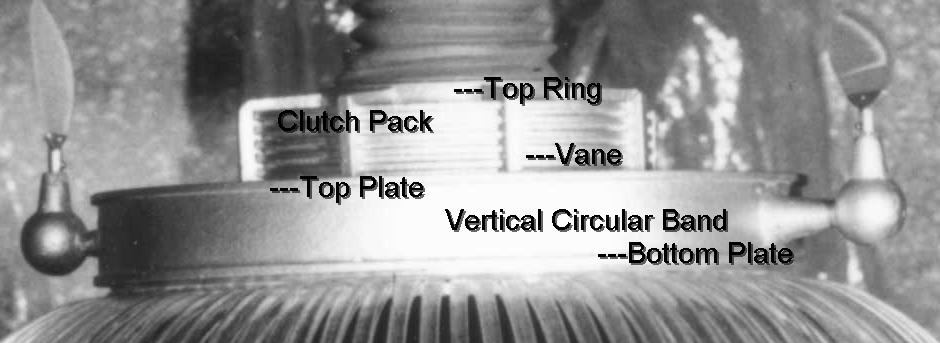

THE ALUMINUM RADAR

As discussed elsewhere on this website, my radar is being manufactured out of 2024 aluminum so that it can be anodized for durability and protection. Because 2024 aluminum is difficult to weld, the radar will be held together by hidden bolts. My machinist cleverly came up with the ingenious design for holding the different elements of the radar together.

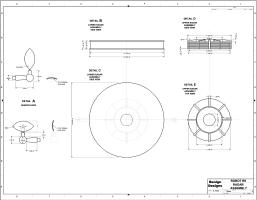

My machinist is using Dave Painter's Robot Blueprints as his guide. These are available from the members only section of the B9 Robot Builders Club website.

Ignoring

the spinner posts for now, the radar

is composed of six basic elements:

The top ring

The clutch pack (comprising 10 discs)

The 8 vanes

The top plate

The vertical circular band

The bottom plate.

THE TOP RING

The top ring is machined out of solid aluminum.

The top ring is pictured here upside down so that you can see the

tapped

and threaded screw holes. Long bolts will come up through the inner

margin

of the vane slots. Once the eight bolts are screwed into the top ring,

they will hold the clutch pack tightly against the top plate.

The slight taper (or "cant") is created on a lathe.

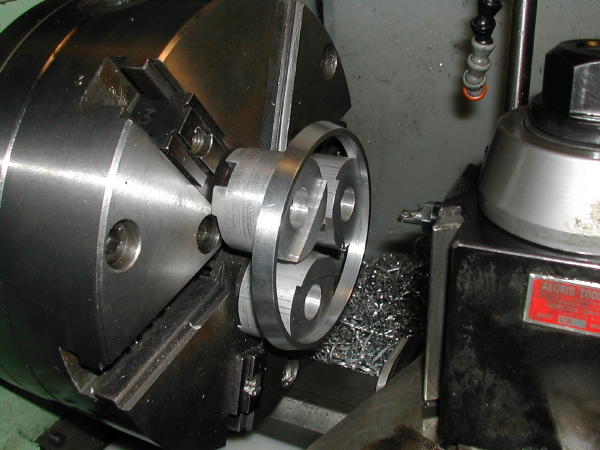

THE CLUTCH PACK

The clutch pack is composed of ten disc: five of a larger diameter; and five of a smaller diameter. There are thirty discs in this photograph because I am having three radars manufactured: one for me, and two for any robot builders who want one. Because of standard sizing for aluminum sheet, the unit cost per radar was dramatically less if I had three made than if I only had one made.

The discs were machined out of solid aluminum plate. The slots for the vanes were cut using a high precision CNC (Computer Numerical Controlled) milling machine.

The length of the slot is slightly greater than the length of the vane so that a hidden bolt can run up through the slot and screw itself into the top ring. Another bolt will run up from the top plate into the vane near the outer perimeter of the clutch pack.

THE VANES

These have not yet been finished. The rough

blocks

have been milled, but they require machining to create the slight rise

along the top plane. It is also necessary to angel the inner plane so

that

it perfectly matches the taper of the top ring.

In the

photograph below, you can see the gap created

by the taper of the top ring. Once the vanes have been machined, they

will

fit perfectly into this odd space.

THE TOP

PLATE

The top plate is unique in that it has two tapped

holes per vane drilled into it through which the bolts that hold the

clutch

pack will run.

THE

VERTICAL CIRCULAR BAND

The band is created from a single strip of aluminum. It will be rolled on a rolling machine and very carefully welded together. The seam will then be machined so that it becomes nearly invisible. I mentioned above that 2024 aluminum is difficult to weld. Nevertheless, with expert skill, and with the right sort of aluminum weld bar, it can be accomplished. Although one will never be able to detect the weld seam by touch, it may be slightly visible as a faint shadowy vertical line. This is caused by the weld bar. The seam will be placed in the back of the radar, but my machinist assures me that the seam will nevertheless be almost impossible to detect unless it is pointed out.

Here is a

photo of my shy machinist holding the

raw stock that will be rolled to create the band.

THE BOTTOM PLATE

The photograph above shows the underside of the bottom plate. It has yet to have most of its inner material cut away. Once finished, it will take the shape of a ring designed to fit exactly over the 12-inch Rockler turntable that I am using.

The outer ring of eight counter-sunk screw holes on the underside of the bottom plate are part of the hidden system designed by my machinist to attach the vertical circular band to the bottom plate.

The inner ring of right smaller screw holes line up with the corresponding screw holes in the Rockler turntable. Thanks to my machinist's flair for mechanical design, a perfect system for attaching the radar to the turntable has been devised! I am very proud of him.

PARTING

SHOTS

Once the vanes are machined, the bottom plate has its interior cut out, and the holes are drilled into the vertical band to receive the spinner posts, the pieces of the radar will be ready for anodizing. After anodization, the radar will be ready for assembly and mounting on my robot. In a few weeks, all three radars should be finished. I can hardly wait.

Stay

tuned for more updates!