ALUMINUM

RADAR

Now Ready!

| Home | Back | Previous Page | Next Page | October Progress Page |

ALUMINUM

RADAR

Now Ready!

I picked up two completed aluminum radars from my machinist today. They are both for sale. My own radar is still being completed. It should be ready in about two weeks. The delay is due to the anodization process that I have chosen for my own radar.

As you will have read in the radar update in my October progress section, I have had these radars manufactured out of 2024 aluminum. Each radar weighs just under ten pounds. The radar was made using Dave Painter's robot blueprints. The only deviation from these blueprints is the canting of the top ring. This alloy can be anodized without discoloration, but it is just as beautiful in its raw state. The following photographs depict the radars in their pristine, unanodized, unbeadblasted state. I like the look of the raw aluminum so much that I have been tempted to forgo anodization.

Click on

the thumbnail image to see the full-size

photograph

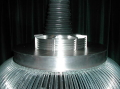

Here is the assembled radar

sitting atop a beautiful Lorenzo d'Alessandro

laser-cut collar. The radar is obviously heavier than an acrylic radar,

but it places no strain of any kind on the collar. The d'Allessandro

collar,

I should point out, is made incredibly sturdy by hidden vertical

reinforcing

rods on the interior. It is the perfect collar for my aluminum radar.

The

fine rubber bubble lifter is a Dewey Howard creation. Look closely, and

you can see the gentle radius on the top corner of each vane. A fine

craftsman

touch added by my machinist.

Here is the assembled radar

sitting atop a beautiful Lorenzo d'Alessandro

laser-cut collar. The radar is obviously heavier than an acrylic radar,

but it places no strain of any kind on the collar. The d'Allessandro

collar,

I should point out, is made incredibly sturdy by hidden vertical

reinforcing

rods on the interior. It is the perfect collar for my aluminum radar.

The

fine rubber bubble lifter is a Dewey Howard creation. Look closely, and

you can see the gentle radius on the top corner of each vane. A fine

craftsman

touch added by my machinist.

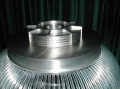

Here is another shot of the radar with the bubble

lifter removed. You can

see the nice taper to the center ring. Many thanks to builder Marc

Chabot

for pointing out this feature on the hero robot costume. Thanks also to

Michael Davis for highlighting this often overlooked detail of the

radar

of the stunt robot on his website.

Here is another shot of the radar with the bubble

lifter removed. You can

see the nice taper to the center ring. Many thanks to builder Marc

Chabot

for pointing out this feature on the hero robot costume. Thanks also to

Michael Davis for highlighting this often overlooked detail of the

radar

of the stunt robot on his website.

Here is another shot of the radar, revealing the ten

discs of the clutch

pack.

Here is another shot of the radar, revealing the ten

discs of the clutch

pack.

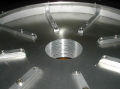

In this shot of the radar turned upside down, you can

see the eight internal

ribs that hold the entire radar together. Hidden screws pull all the

pieces

tightly together. One ring of screws terminates within the eight vanes.

The other ring of screws terminate within the top ring. My machinist

said

that he was able to assemble the radar in ten minutes. The advantage of

using screws is that the radar can easily and quickly be disassembled

if

one ever wanted to make modifications to it. If you wanted to reduce

the

weight of the radar, you could unbolt the radar, and then cut away

internal

sections of the clutch pack.

In this shot of the radar turned upside down, you can

see the eight internal

ribs that hold the entire radar together. Hidden screws pull all the

pieces

tightly together. One ring of screws terminates within the eight vanes.

The other ring of screws terminate within the top ring. My machinist

said

that he was able to assemble the radar in ten minutes. The advantage of

using screws is that the radar can easily and quickly be disassembled

if

one ever wanted to make modifications to it. If you wanted to reduce

the

weight of the radar, you could unbolt the radar, and then cut away

internal

sections of the clutch pack.

The radar has been designed to work with the Rockler

12" turntable. In

this shot, the radar is upside down and the Rockler turntable has been

put in position.

The radar has been designed to work with the Rockler

12" turntable. In

this shot, the radar is upside down and the Rockler turntable has been

put in position.

Here, you can see how the screw holes in the Rockler

turntable line up

with screw holes in the bottom plate of the radar. Four bolts (supplied

by the machinist for free) hold the turntable to the radar.

Here, you can see how the screw holes in the Rockler

turntable line up

with screw holes in the bottom plate of the radar. Four bolts (supplied

by the machinist for free) hold the turntable to the radar.

In this shot, the turntable has been place face side

up. I have placed

the bottom plate and vertical band from my own unfinished radar on top

of the radar to illustrated how everything fits together. The machined

spinner post depicted in the photograph was made using the dimensions

provided

in Dave Painter's blueprints.

In this shot, the turntable has been place face side

up. I have placed

the bottom plate and vertical band from my own unfinished radar on top

of the radar to illustrated how everything fits together. The machined

spinner post depicted in the photograph was made using the dimensions

provided

in Dave Painter's blueprints.

For my

own radar, holes will be drilled into the

vertical band to receive the peg of the machined spinner posts. The peg

will have threads cut into it so that the spinner post can be held

tightly

and securely in place by a hidden nut on the inside of the radar. This

is an ingenious concept invented by my brilliant machinist.

In this photograph, you can see the one minor flaw in

the aluminum radar.

A tiny hairline wrinkle is visible where the vertical band has been

welded

on the inside. The glaring flash on my camera makes the flaw seem worse

than it really is. This flaw is nearly invisible unless it is pointed

out.

I will be placing this weld seam at the back of the radar, so no one

will

ever see it anyway. Bead blasting, buffing, or painting would probably

cover all traces of this seam.

In this photograph, you can see the one minor flaw in

the aluminum radar.

A tiny hairline wrinkle is visible where the vertical band has been

welded

on the inside. The glaring flash on my camera makes the flaw seem worse

than it really is. This flaw is nearly invisible unless it is pointed

out.

I will be placing this weld seam at the back of the radar, so no one

will

ever see it anyway. Bead blasting, buffing, or painting would probably

cover all traces of this seam.

What

remains to be done?

1. Machining of new spinner posts using Craig

Reinbrecht's blueprint for a first-season spinner post. Spinner

posts

will have threaded pegs as explained above.

2. Anodizing of all parts of my radar, including

the spinner posts

3. Attachment of brackets on the inside of my

radar to hold the Warner Electric

linear actuator

motor that will lift the bubble.

4. Attachment of brackets on the Rockler

turntable

to hold the motor that will spin the radar.